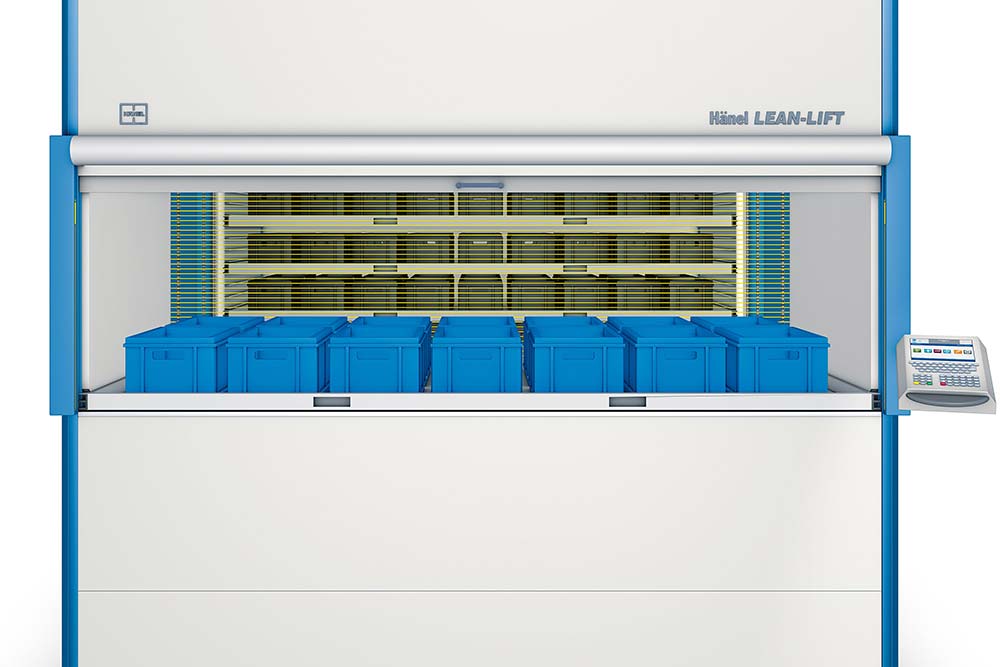

HÄNEL Lean-Lift automated storage systems

Hänel Lean-Lift automated storage systems combine storage with inventory protection and efficiency.

The goods are delivered on demand to the retrieval area at the correct ergonomic height, thus avoiding strain or injury.

Lean-Lift vertically stores a large quantity of your goods, in height-optimized locations, as defined by an operator or the built-in software.

The integrated technology ensures stock transparency, restricting access as necessary, and keeping a full record of who took what and when.

Improve stock control and security

Storing and accessing all of your valuable goods should never be compromised. The Hänel Lean-Lift automated storage units allow you to manage and better consolidate your inventory, at the same time adding a high level of security. The storage system has a variety of built-in security features ranging from PIN protection to electronic fingerprinting, with the option to include automated security doors and camera/CCTV monitoring – thus preventing unauthorized access.

Smart systems

Using current technology, the system controllers can be easily integrated into your IT interface, creating the ultimate storage management system. Smart control devices and software solutions enable a seamless operation for your warehouse.

Technical specifications

Storage trays

From multiple trays with slotted holes and movable dividers, to trays with adjustable front walls, you will receive a truly custom-made solution for your individual needs.

The size and weight of the stored goods will determine the components of the storage system and will be adapted to your future needs and growing product range, while still achieving maximum efficiency of total storage volume.

General features:

- Bearing capacity up to 1000 kg per tray

- Maximum storage capacity per unit up to 60 tons

- Long lifecycle

- Optional intermediate shelves and dividers possible

Access points

Depending on the application, the Hänel Lean-Lift automated storage units can be fitted with access points customized according to individual requirements:

- Each tray can be weighed in the access area by an electronic 4-point weighing system

- Fold-down support rails fitted with plastic rollers to allow for trays to be pulled out, if necessary

- Syncronized control

- Support for manual transport when collecting trays from the access area

- Variable heights of the access point, depending on the goods stored

- With manual or automatic sliding doors

Thanks to the photocell curtain, the operator is protected from any potential injury during operation of the automated storage unit.

For larger storage systems located on many floors, you can opt for multiple access points, enabling access to personnel from different departments. This allows the personnel to access the needed items in a fast and efficient way.

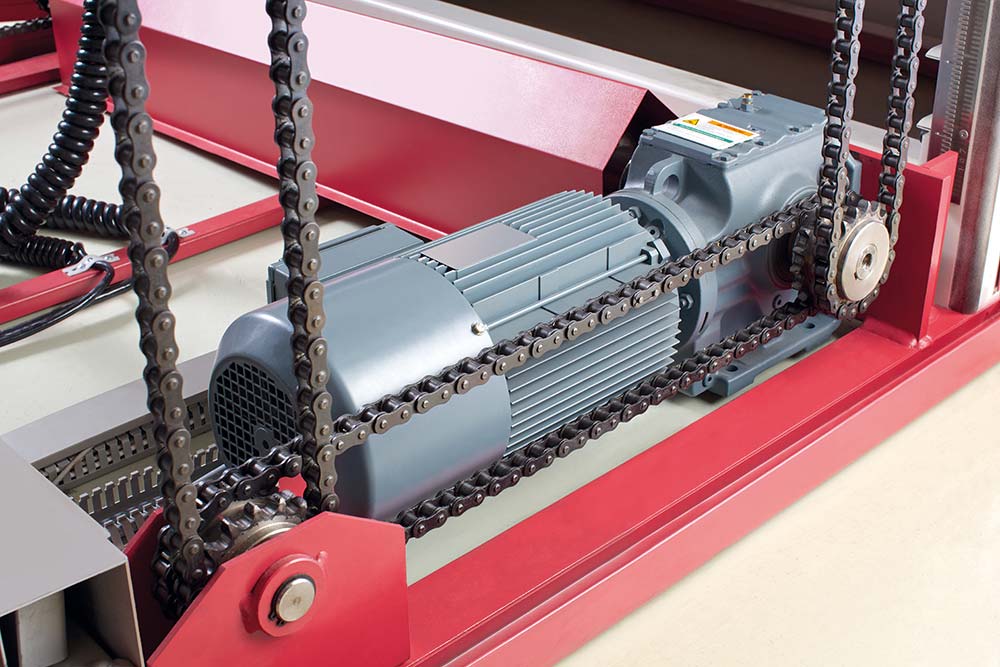

Drive components

The motors in the Lean-Lift automated storage units ensure fast acceleration and smooth braking at all times. For example, the vertical traveling speed for trays with a load capacity of up to 500 kg is 2.3 m/s with an empty extractor and 1 m/sec with a loaded extractor. Horizontally, the extractor travels at a speed of 0.5 m/sec.

The Lean-Lift storage system is equipped with a 4-point suspension extractor that uses the 4-chain technology.

Operational safety

The Lean-Lift automated storage unit is equipped with multiple sensors and safety features that ensure accuracy and safety at all times. The MFPS-2 system enables the exact positioning of containers. With sensors on both sides of the extractor, deviations are within a maximum range of +/- 1 mm. The photocell curtain guarantees maximum safety for users when handling goods in the access area.

Multifunction positioning system

This automated storage equipment is fitted with a multifunction positioning system where built-in light sensors measure the height of the storage trays for an optimal storage density on multiple levels.

When you store items of different sizes, the sensors measure these items, and the microprocessor control system finds the best storage location in Lean-Lift – regularly achieving a density ratio of over 95%.